6-cubes biogas installation with two reactors

6-cubes biogas installation with two reactors

Composition of installation

Placement of installation

Exploitation of installation

Payback of installation

6-cubes biogas installation with two reactors

Composition of installation

6-cubes biogas installation consists from a 300 litres container for preparation of raw material, a feeding system of raw material, two consistently paired reactors on 3 cubic meters each with systems of electroheating, mixing and warming, system of drainage of raw material, a gas-holder of 1 cubic metre, gas system and the block of automatics.

Placement of installation

For placement of installation there is enough platform 6х6 square meters. The platform is recommended to be concreted. On angles of the platform it is necessary to put poles on which to reinforce a light roof. From one of poles it is necessary to lift a lightning rod, also to make a contour of ground connection. The platform is desirable for closing an enclosuring. It is necessary to bring water and the three-phase power supply 380V to the platform. Wires of the power supply should be calculated for a current up to 25A.

In one angle of the platform it is necessary to establish the platform welded from metal corners in height about 2,5 m with a ladder downwards. On the platform the preparatory container will be installed.

In an installation site of a gas-holder it is necessary to wall metal loops in a concrete floor for fixation of an axis of a gas-holder.

From preparatory container the sewer approaches to bottom of the first reactor. The second reactor is installed near to the first and connected to it approximately on the middle of height. From bottom of the first and second reactors systems of drainage are installed. In the first reactor it is for the emergency, and in second — nominal. In free part of the platform the gas-holder is placed. On the platform for preparation of raw material the block of automatics and gas system is installed.

Exploitation of installation

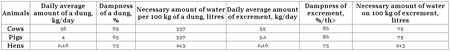

Before the first start in both of a reactor it is necessary to fill in\ 4,8 cubic meters of the prepared intermixture. For the first batch presence at an intermixture of a significant amount of a dung of large beeves or other raw material containing anaerobic bacteria is desirable. To prepare for an intermixture it is possible, using the following table:

Excrement are an intermixture of a dung and urine which gathers on farms.

The first batch is made by rations approximately on 250 l the intermixture prepared according to the table. After filling reactors the block of automatics turns on and the warming up of an intermixture up to working temperature begins. On operating duty installation can leave in a week after the first batch.

First two complete gas-holders of gas are necessary for pitting, as in them there will be the initial air remained in reactors and a carbon dioxide, evolved in the beginning of response. After that installation passes in a standard duty. Biogas can use. Every day it is necessary to drain off 240 litres of slimes after mixing contents of reactors, and in exchange to fill in 240 litres of a fresh intermixture. If in a gas-holder is more than 240 litres of gas it is possible to drain off all over again, and then — to fill in. If it is not enough gas, to fill in and drain off it is necessary simultaneously.

For maintenance of biogas installation with raw material there are enough 2-3 cows, 25-30 pigs, 450-500 hens. Daily allowances production of biogas will make 6,5 cubic metre for a dung of cows, 11 cubic metre for a hog manure, 12 cubic metre for a poultry excreta.

These numerals are given for a mesophilic duty of installation at 35°С. For a thermophilic duty the gas discharge will increase approximately in 2 times, also in 2 times the cycle, and, accordingly, a daily batch will be accelerated by raw material will increase up to 480 litres. But thus the rate of flux of the electric power on heating of reactors will grow. If at a mesophilic duty such installation will monthly consume an electricity on 5-10 USD, depending on the tariff of payment in a thermophilic regime it will consume the electric power on 16-32 USD in a month.

Produced amount of biogas will be enough for heating, for example, well warmed individual house heated by the modern gas boiler.

Payback of installation

6-cubes biogas installation will produce 240 litres of biofertilizings day. In a year the yield of fertilizings will make 87,6 tons that is enough for fertilizing, for example, 218 hectares of wheat. The incremental value of productivity thus will make from 10 up to 35 additionalhundredweights per hectare. At the minimum cost of wheat 60 USD for ton the additional profit will make more than 13000 USD.

The market value of ton of such fertilizings equals approximately 120 USD for ton. If to organize sales of fertilizings the income will make 10512 USD.

Cost of such installation with installation and delivery equals 9900 USD. Annual rates of flux on electricity — a maximum 120 USD. Thus, in any event installation pays off for one season.